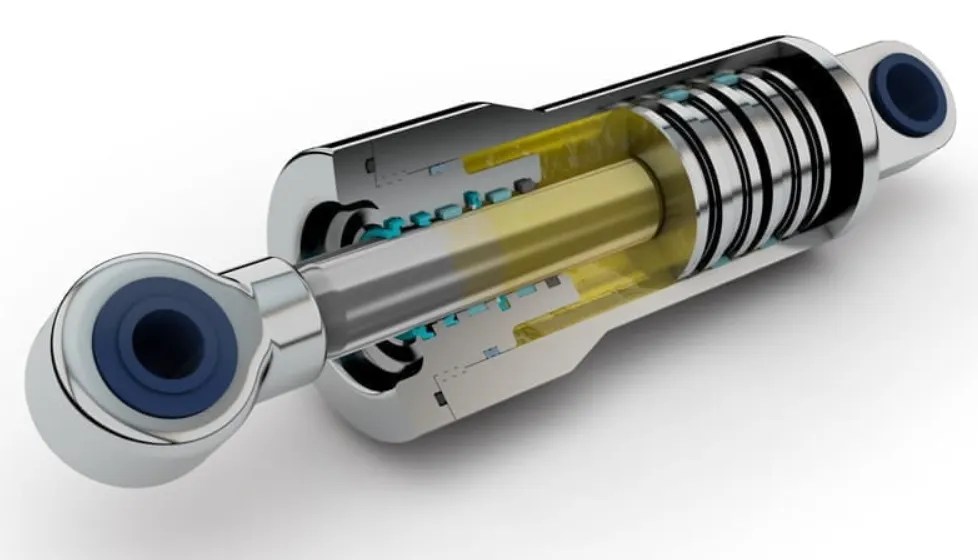

Fluid leakage in pistons is a common challenge in many industries. From automotive to manufacturing, preventing fluid loss is crucial for maintaining the efficiency and longevity of machinery. This blog post explores innovative sealing solutions designed to tackle this issue head-on. For young engineers and technicians looking to optimize their equipment, this guide offers practical insights to ensure your systems run smoothly.

Contents

Understanding the Importance of Sealing Solutions

Sealing solutions are essential for preventing fluid leakage in pistons. They help maintain pressure, protect against contaminants, and ensure smooth operation. Without effective seals, machinery can suffer from reduced performance, increased wear, and potential breakdowns.

Types of Seals for Pistons

Hydraulic Seals

Hydraulic seals are critical components used in various applications to contain fluid and prevent leaks. These seals are designed to withstand high pressures and temperatures, making them ideal for demanding environments.

O-Rings

O-rings are versatile and widely used seals. They are typically made from rubber and can fit into a wide range of applications. O-rings provide a reliable seal by compressing into a groove, forming a barrier against fluid leakage.

Lip Seals

Lip seals are designed with a flexible lip that makes contact with the piston surface. This design helps to create a tight seal while allowing for movement. Lip seals are commonly used in dynamic applications where motion is involved.

Choosing the Right Material

Rubber Seals

Rubber is a popular choice for seals due to its flexibility and durability. It can withstand a range of temperatures and pressures, making it suitable for various applications. Rubber seals are often used in automotive and industrial settings.

PTFE Seals

PTFE (Polytetrafluoroethylene) seals are known for their high resistance to chemicals and extreme temperatures. They are ideal for applications involving aggressive fluids or harsh environments. PTFE seals offer long-lasting performance and reliability.

Metal Seals

Metal seals provide excellent mechanical strength and resistance to high pressures. They are often used in applications where rubber or PTFE seals may not be suitable. Metal seals are commonly found in heavy machinery and high-pressure systems.

Installation Best Practices

Proper installation is crucial for ensuring the effectiveness of sealing solutions. Here are some tips to keep in mind:

Clean Surfaces

Before installing seals, make sure all surfaces are clean and free from debris. Contaminants can compromise the seal and lead to leaks.

Use Lubricants

Lubricants can help ease the installation process and prevent damage to the seal. They also reduce friction during operation, extending the life of the seal.

Follow Manufacturer Guidelines

Always follow the manufacturer’s guidelines for installation. This includes proper sizing, alignment, and torque specifications.

Common Causes of Seal Failure

Improper Installation

Incorrect installation is one of the leading causes of seal failure. Ensure that seals are installed correctly to prevent leaks and prolong their lifespan.

Wear and Tear

Over time, seals can wear out due to constant use and exposure to harsh conditions. Regular maintenance and inspection can help identify worn seals before they cause problems.

Chemical Degradation

Certain chemicals can degrade seals, causing them to lose their effectiveness. Choose seals made from materials that are compatible with the fluids they will encounter.

Maintenance Tips for Sealing Solutions

Regular Inspections

Perform regular inspections to check for signs of wear or damage. Early detection can prevent leaks and extend the life of your seals.

Replace Worn Seals

If you notice any signs of wear or damage, replace the seals immediately. Delaying replacement can lead to more significant issues and costly repairs.

Monitor Operating Conditions

Keep an eye on the operating conditions of your machinery. Excessive heat, pressure, or exposure to chemicals can accelerate seal degradation.

Benefits of Using High-Quality Seals

Improved Performance

High-quality seals ensure optimal performance by maintaining pressure and preventing fluid leakage. This leads to smoother operation and increased efficiency.

Reduced Maintenance Costs

Investing in high-quality seals can reduce maintenance costs by minimizing the need for frequent replacements and repairs.

Enhanced Equipment Lifespan

Effective seals protect your equipment from contaminants and fluid loss, extending its lifespan and reducing downtime.

Innovations in Sealing Technology

Self-Lubricating Seals

Self-lubricating seals are designed to reduce friction and wear. They incorporate lubricants within the seal material, providing continuous lubrication during operation.

Advanced Composite Materials

New composite materials offer enhanced performance and durability. These materials combine the best properties of multiple substances, resulting in seals that can withstand extreme conditions.

Smart Seals

Smart seals incorporate sensors that monitor seal performance in real-time. They can detect leaks, wear, and other issues, providing valuable data for predictive maintenance.

Conclusion

Effective sealing solutions are vital for preventing fluid leakage and ensuring the smooth operation of machinery. By choosing the right seals, following proper installation practices, and performing regular maintenance, you can enhance the performance and lifespan of your equipment. Stay informed about the latest innovations in sealing technology to keep your systems running efficiently.